Processing technology of Jiangmen engineering plastics

Processing technology of engineering plastics

1. Plastic processing function

Plastic processing function refers to the function of processing raw materials (such as various profiles) into high-quality parts (blanks or products) through plastic processing (forging, stamping, kneading, rolling, etc.). It depends on the size of the plastic bump and deformation resistance (resistance to deformation) of the data itself.

The intention of plastic processing is to make the data produce plastic deformation under the action of external force (load) and form, so as to achieve better functions. The data with small plastic resistance show that deformation can be carried out under the action of not too large external force. In the metal data, copper, aluminum and low carbon steel have good plasticity and small deformation resistance, so they are simply plastic processed and formed, while cast iron cemented carbide cannot be plastic processed and formed, and thermoplastic plastics can be kneaded and molded.

2. Heat treatment function

The heat treatment function mainly refers to the ability of steel to withstand quenching (hardenability). It is indicated by the hardened layer test. Different steels have different ability to withstand quenching. The hardenability of alloy steel is better than that of carbon steel, which means that the hardenability of alloy steel is thick. It is also clarified that uniform quenching structure and uniform mechanical function can be obtained after large parts are made of alloy negative.

3. Welding function

Welding function refers to the function of two identical or different materials connected together by heating, pressurization or both. There are many factors affecting the welding function, such as too high or too low thermal conductivity, high thermal expansion coefficient, low plasticity or simple oxidation during welding. The welding function is generally poor. After welding, the weld strength is low, and deformation and cracking may occur. Selecting special process can not only weld metal to metal, but also weld metal to ceramic, ceramic to ceramic and plastic to sintering materials.

4. Cutting function

The cutting function refers to the function displayed when the data is processed with cutting tools. It determines the service life of cutting tools and the surface roughness of machined parts. The cutting function is good for the data with long service life and low surface roughness after machining; On the contrary, the cutting function is poor.

The cutting function of metal data is mainly related to data type, composition, hardness, resistance and thermal conductivity. The ideal cutting hardness of general steel is 160-230hb. The hardness of steel is too low, and the tool is simply stuck during cutting; The surface roughness is high, the hardness is too high, and the cutting tool is easy to be worn during cutting.

Source: Jiangmen engineering plastics http://m.feimandao.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

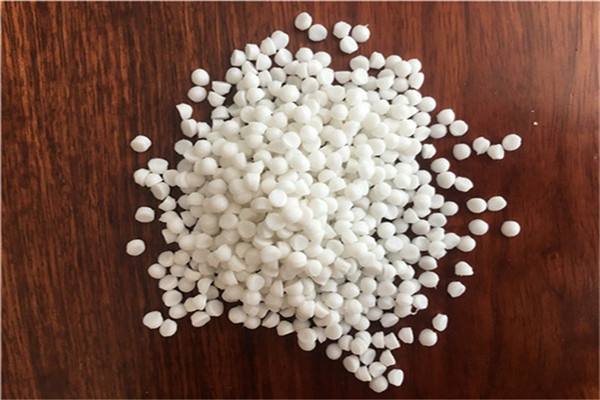

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t